Case Study

High-Speed Connectivity

We partnered with a worldwide construction company and French National Railway Utility to deliver reliable and long-lasting solutions.

302 km of High-Speed Line and 40 km of Connection to the Existing Line

The S.E.A (South Europe Atlantic) line, is a high-speed line between Tours and Bordeaux, in France. With 302 km of a new line and 40 km of connection to the existing one, this was one of the biggest railway projects all over Europe. The economical development of the territory, as well as the implementation of sustainable mobility, were the key issues of this initiative.

The Challenge

The S.E.A., South Europe Atlantic, project was a completely new rail high-speed line in France. An OEM won the construction contract and needed a partner in critical supply for the construction of the overhead line. The LGV S.E.A. Tours - Bordeaux line has 340 km of new rail lines including 302 km of high-speed line and roughly 40 km of connection to the existing line. It goes through:

- 3 regions

- 6 departments

- 113 towns

- 320 km/h speed

- 13,000 catenary poles

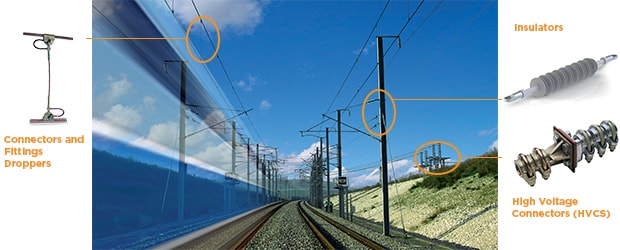

For a project of this scope, the construction company needed insulators, connectors, and fittings qualified by the national rail utility, to ensure connections across the line. They also needed a partner they could count on for rapid response and support. Being qualified by the French national railway utility means:

- Long-lasting products to reduce maintenance need and ensure safety

- Reliable products ensuring the highest quality, while allowing network reliability and high-speed train availability

- High technical products meeting demanding performance specifications

The Solution

TE's advantage combines multiple decades of global insulator design experience, along with Raychem material expertise. Our specially formulated EVA (Ethylene Vinyl Acetate) formulation brings superior pollution resistant covering, with superior acid and chemical resistance advantage, stemming from the semicrystalline structure of the base EVA polymer: a key advantage over the softer amorphous structure of silicone insulators.

In addition to that, 10 years of studies and experimentation allowed TE to obtain the certification of the French national railway company.

With a wide range of connectors and the droppers solution, we offered a reliable and long-lasting solution. Our dropper is articulated at both the upper and lower part in order to improve electrical and mechanical behavior. Thanks to its design, this connection dropper passed all the tests defined in the national company’s specification (mechanical, electrical and oscillation tests).

60k

60,000 insulators for S.E.A.

20K

20,000 insulators for high speed line East Extension 2

25

References of connectors and fittings, including 120,000 droppers

The Outcome

We have many years of expertise in designing and supplying products for demanding rail applications. Thanks to our experience and our compliance with the French National Railway Utility's specifications, we were selected to design, test and manufacture insulators, droppers and connectors for this new project.

One of our insulators range also received homologation from the French National Railway Company to be installed the French rail networks. This has allowed TE Connectivity to become a key supplier in France for the insulators' product range specifically for High-Speed Rail (HSR) projects. TE rail insulators were installed in Eastern France on the Paris to Strasbourg HSR extension project and on the S.E.A. project, from Tours to Bordeaux.

“TE demonstrated their strength in an uncommon context. They clearly positioned themselves as a key railway supplier thanks to offering all possible connection solutions. TE quality expertise and special understanding of our needs made them the best choice.”