RTD & Thermocouple Basics

Q: What is an RTD?

A: An RTD (Resistance Temperature Detector) is a sensor whose resistance changes as its temperature changes. The resistance increases as the temperature of the sensor increases. The resistance versus temperature relationship is well known and is repeatable over time.

An RTD is a passive device. It does not produce an output on its own. External electronic devices are used to measure the resistance of the sensor by passing a small electrical current through the sensor to generate a voltage.

Read More: Understanding RTDs

Q: What is a thermocouple?

A: A thermocouple is a device consisting of two different conductors (usually metal alloys) that produce a voltage proportional to a temperature difference between either ends of the pair of conductors. In contrast to most other methods of temperature measurement, thermocouples are self-powered and require no external form of excitation

Read More: Thermocouple Types

Q: What is the difference between an RTD and thermocouple?

A: The three main differences between RTDs and thermocouples are their temperature range capability, accuracy / stability, and response time.

Temperature:

- RTD: narrower temperature range: -200 to 600°C

- Thermocouple: wider temperature range: -200 to 2000°C

Accuracy/Stability:

- RTD: capable of higher accuracy and can maintain stability for many years

- Thermocouple: less accuracy and can drift in shorter periods

Response Time:

- RTD: 1 to 7 seconds

- Thermocouple: less than one second

Read More: RTDs versus Thermocouples

Q: What type of temperature sensor should I use for my application?

A: The type of temperature sensor is primarily dependent on two factors:

1. Whether you are currently using any process control devices; if you currently have process control system in place, the devices you are using will dictate the type of sensor you need.

2. Whether you are building a new process control system; If you are establishing a new control system, then we suggest using a 100 ohm platinum RTD, due to its availability, as well as wide variety of controlling and monitoring devices designed for this type of sensor in the marketplace.

Q: What is the advantage between using three leadwire and two leadwire?

A: Leadwires distort the resistance and thus temperature readings. The longer the leadwires, the more they over read the resistance and thus will give you higher temperature reading then the actual temperature at which you are trying to measure. By adding a 3rd leadwire, it can cancel the readout effect of the first two leadwires.

Q: Why are there different types of alpha curves for platinum RTD element?

A: Different agencies or organizations (i.e. governmental, industrial and trade) have defined curves in an effort to develop a standard by which all manufacturers can operate. Some were developed by individual manufacturers based on their own abilities to offer a reproducible curve.

Q: How do I know what type of alpha curve I need to use?

A: When choosing a curve for a particular application, there are considerations to keep in mind. 1. Existing, or proposed instrumentation. The sensor and sensor input curves must match. 2. Cost. It may be more expensive to achieve 0.003926 curve than 0.003850 curve.

Q: When do I need a transmitter?

A: There are a few reasons to use transmitters;

1. To amplify sensors output signal. This becomes critical if the sensor is located far away from the instrumentation or if there is electrical noise that distorts the sensor output.

2. To improve the functionality of temperature measurement.

3. To convert the sensor signal to standard signals, such as 0-20, 4-20mA.

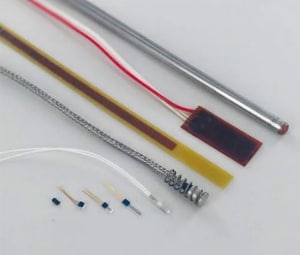

Q: What are the main differences between thin-film element and wire-wound element?

A: A thin film element is manufactured by using a highly sophisticated technology called photolithography. This technology enables sensing element to be more rugged, smaller in size, more accurate, and more cost effective than traditional wire-wound elements. Since wire-wound elements are labor intensive, they tend to be more expensive.

Q: What is an element?

A: An element is the component, which actually does the measuring. Based on the function, it is going to perform and the technology employed in fabricating it, an element can have coils and/or different patterns to provide a signal, which then is used to measure the changes in different properties of energy.

Q: What is a cold junction?

A: A junction is a point where two dissimilar metals are joined.

1. Cold junction (also known as a reference junction); a thermocouple junction, which is held at a known and stable temperature. The standard temperature used for this function is 32°F (0°C).

2. Hot junction (also known as a measuring junction); a junction, which detects the temperature of unknown object or environment.

Q: What are the advantages and disadvantages of grounded thermocouples?

A: A grounded junction puts the junction in contact with the packaging, protecting, metal case. This allows for a faster response time, however, a grounded tip is susceptible to electromotive forces in the environment, which might cause potential errors in the measurement. An ungrounded junction, therefore, is one without a contact with the metal case. Thus, have slower response time, but is less likely to provide erroneous readings.