Miniature Automotive Terminals & Connectors for Space & Weight Savings

As electrical content in vehicles continues to increase, the need for miniaturized automotive terminals and connectors is greater than ever. Manufacturers can achieve strategic weight savings goals, PCB footprint and emissions reductions by using TE Connectivity’s (TE) miniaturized connector systems while providing true automotive-grade robustness and reliability when deployed in harsh, high-vibration, high temperature automotive environments. Supporting a blade size of 0.50mm and a wire range of 0.13mm2 – 0.35mm2, TE’s miniaturized portfolio is designed to meet the most stringent OEM specifications such as LV214 and USCAR while enabling space savings of up to 78% (when compared to MQS).

0.13mm2

0.13mm2 - 0.35mm2 wire sizes supported

78%

Up to 78% weight reduction

30%

Reduction in pin-pitch

Product Family

|

Terminal Size

|

Minimum Pitch

|

Max. Current @ 80C

|

Max. Vibration Class

|

Termination Type

|

Validated Wire Sizes (mm²)

|

Sealed/ Unsealed

|

OEM Specification

|

0.50 mm |

1.27 mm |

4 Amps |

SG2 |

Crimped |

0.13 – 0.35 (0.22 FLU/FLR) |

Unsealed |

LV214/VW75174 |

|

0.50 mm |

1.8 mm |

6 Amps |

SG4 |

Crimped and FFC |

0.13 – 0.35 |

Sealed/ Unsealed |

LV214/USCAR |

|

0.50 mm |

1.8 mm |

3 Amps |

SG4 |

Crimped |

0.13 – 0.35 |

Sealed |

L214/USCAR |

|

0.50 mm |

1.8 mm |

4 Amps |

Vibration Class 1 |

Crimped |

0.13 – 0.35 |

Sealed/ Unsealed |

USCAR |

|

0.50 mm |

1.5 mm |

5 Amps |

Vibration Class 1 |

Crimped |

0.13 – 0.35 |

Sealed/ Unsealed |

Japanese OEMs |

This product table can only be viewed on desktop.

New - PicoMQS Automotive-Grade Miniaturized Connector System

- Automotive-grade robustness with Class 2 vibration stability

- 30% reduced pin pitch with 1.27mm pitch

- 55% reduction in crimp length

- 78% reduced packaging weight (compared to MQS)

- 40% space savings (compared to NanoMQS)

- Smallest LV214 qualified crimped connection

- 0.22 wire carrying up to 4 amps

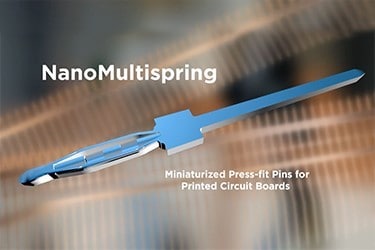

- S-bending solder pin design with a reduced pin length by 4mm (42% shorter length)

- Manufacturing ease, quality and cost efficiency

Miniature Automotive Connectors by Series

The PicoMQS connector system is used in connections within vehicle sub-systems or modules, often known as blackboxes, including headlamp and steering wheel units as well as vehicle cameras. In addition, the PicoMQS connector system can support flat-flexible (FFC) and flexible-printed (FPC) cables often used in EV battery management systems facilitating routing around compact complex battery geometries.

Find PicoMQS Terminals, Connectors and Headers

Based on TE’s highly successful MQS connector system, the NanoMQS offers a locking lance terminal design, which audibly and tangibly latches onto the plastic housing once the terminal is fully inserted. The NanoMQS design has a pin pitch of 1.8mm enabling a PCB footprint reduction by up to 50% while offering up to 6 Amps of nominal current capactity. NanoMQS connectors operate at a maximum operating temperature of 170°C (Ag).

Find NanoMQS Terminals and Connectors

Designed for deployment in very harsh automotive environments, this sealed system offers a ‘clean body design’ with a pin pitch of 1.8mm enabling a PCB footprint reduction by up to 50%. The MCON 0.50 systems meets requirements for LV214 Level 3 for close-proximity installations and Level 4 in the case of direct engine mounting. It also achieves an IPx9k level of water protection, providing the highest level of water and moisture resistance and can be submerged in several meters of water. MCON connectors operate up to 170°C (Ag).

Find MCON 0.50 Terminals and Connectors

TE Connectivity's Generation 50 miniaturized connector system offers clean body and locking lance terminal designs incorporating an anti-stubbing terminal beam geometry lowering the risk of terminal push out. It supports wire sizes of 0.13mm2 to 0.35mm2 as well as PCB retention forces of up to 80N, while meeting USCAR ergonomic requirements.

Find Generation 50 Connectors

Supporting a wire range of 0.13mm2 - 0.5mm2 and providing a pin pitch of 1.5mm, TE Connectivity's 0.50 Series connector system is specifically designed to support high component density as well as automotive-grade robustness. The portfolio of headers includes surface mounting as well as through-hole mounting variants, while the 0.50 Series connectors have a low center of gravity specifically designed for stable surface mounting. In addition, the connectors feature a highly ergonomic design, meaning they are compact and easy to mate.

Find 0.50 Series Connectors

Learn About Our Miniature Capabilities

PicoMQS

PicoMQS NanoMQS

NanoMQS MCON 0.50

MCON 0.50 Generation 50

Generation 50 0.50 Series

0.50 Series