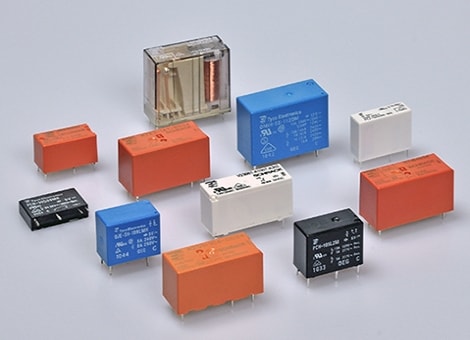

Small, reliable and efficient electromechanical relay solution

AXICOM IM signal relays are small, versatile electromechanical relays that support multiple contact configurations. The low coil power consumption is supporting high-density relay applications reducing overall power consumption. The relay is very shock resistant (up to 300 g force) which is aligned with industrial applications.

TE Connectivity (TE)’s Axicom IM signal relays, as part of our smallest types of electromechanical relays, offer a wide and deep range of variations suitable for many applications. The IM series is equipped with 2 changeover contacts in both monostable or bistable versions, available in multiple coil solutions, performance types, and pin layouts.

Our IM relays are available as slim line 10x6mm, low profile 5.65mm and min. board-space 60mm, for switching current 2/5A, switching power 60W/62.5VA, and switching voltage 220VDC/250VAC. These enable low coil power consumption, with 140mW standard, 100mW for high sensitive version, 50mW for ultra high sensitive version, and 100mW for bistable version. These have high dielectric and surge capability up to 2500Vrms between open contacts and 2500Vrms between coil and contacts. These offer high mechanical shock resistance up to 50g functional. IM relays are typically used in telecommunication, access and transmission equipment, optical network terminals, modems, office and business equipment, consumer electronics, measurement and test equipment, industrial control, medical equipment, and HVAC.

Advantages

- Small electromechanical relay fitting in many continuously shrinking customer applications.

- Contact structure options available (1 form A, 2 form A, 1 form C, 2 form C) which is often not provided without a large cost impact as seen in alternative technologies as solid state relays.

- Switches signal and low power.

- Support battery-powered applications through a bi-stable solution that does not consume constant power.

- Allows application to the PCB in through-hole technology-hole technology (THT) and surface-mount device (SMD) versions. Supporting a high-density customer product footprint, we offer a narrow PCB solder configuration in a THT and 2 SMD versions (SR and JR).

- In high-dense relay applications, we offer a lower coil power version supporting the reduction of overall switching power, which in turn, supports environmental power reduction targets.

- Meeting telecom standards like Bellcore GR 1089, FCC Part 68 and ITU-T K20 for DataComm applications

Technical Features

- Slim line 10x6mm, low profile 5.65mm and min. board-space 60mm2

- Switching current 2/5A, switching power 60W/62.5VA and switching voltage 220VDC/250VAC

- High dielectric and surge capability up to 2500Vrms between open contacts and 2500Vrms between coil and contacts.

- Low coil power consumption, 140mW standard, 100mW for high sensitive version, 50mW for ultra high sensitive version and 100mW for bistable version

- High contact reliability up to 10.000.000 operations

- Very low and stable contact resistance

- THT, SMT design for reflow soldering + providing a smaller footprint option

- High mechanical shock resistance up to 50g functional

Select Applications

IM Relays

- Automotive infotainment systems

- 5G Network systems

- Modems

- Test equipment

- 5G Wireless infrastructure

- Antenna switching

- 5G High speed routers

- Medical ultrasound equipment

- Printers

- IP phones

- Smart Thermostats

- Emergency lighting

- Fire & security control

- Cameras