Press-Fit Technology

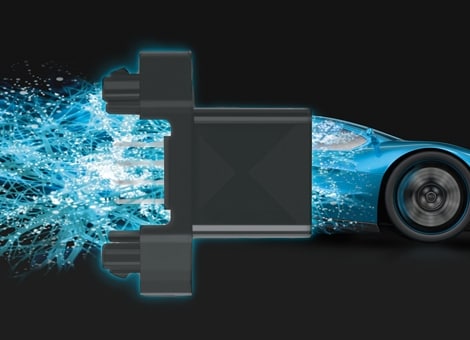

TE Connectivity's (TE) ACTION PIN and Multispring press-fit pins offer compliant pin elastic designs of the press-fit zone providing stress-free, solderless terminal-to-PCB connectivity suitable for the harshest of automotive environments.

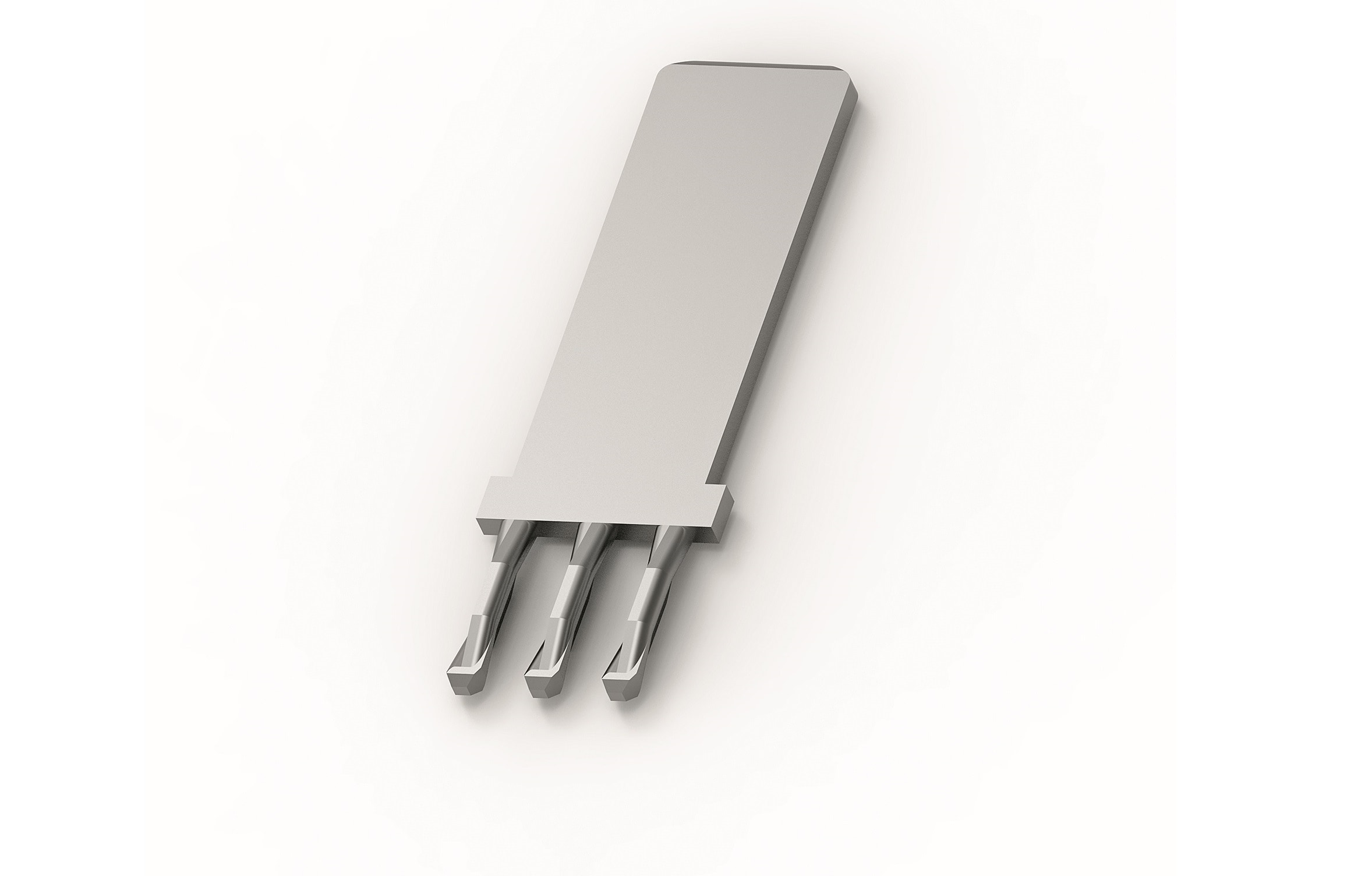

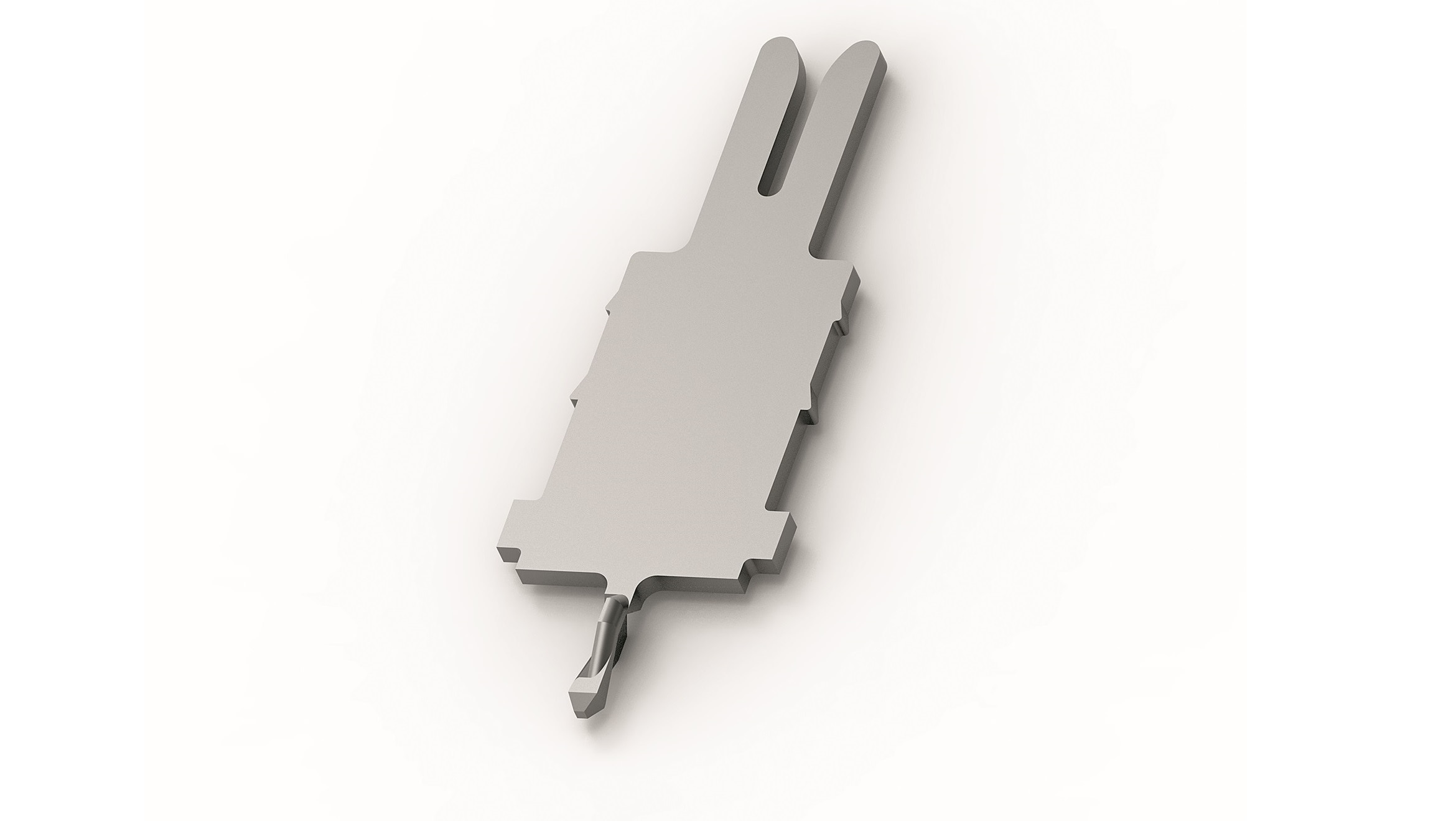

TE offers two distinctive press-fit technologies for automotive applications: ACTION PIN and Multispring, which are both compliant pin designs featuring an elastic behavior during the pin insertion into a Printed Circuit Board (PCB). The press-fit zone will automatically deform during insertion into the PCB to enable a reliable electrical and mechanical connection over its lifetime. The press-fit pin design meets the standardized blade sizes and interfaces of the automotive industry. The ACTION PIN and Multispring press-fit pins can be used in various applications in vehicles from the passenger compartment to the harshest automotive environments, including the engine bay area. Additionally, TE Application Tooling offers matching tooling equipment for single-pin insertion as well as connector seating machines.

Product Introduction

The principle for a press-fit connection is that a contact terminal is pressed into a printed

circuit board (PCB). There are two types of press-fit pins; the solid pin having a solid press-in

zone and the compliant pin having an elastic press-in zone.

Press-fit technology from TE was first introduced in the telecommunication industry in the 1970s. Later, in 1988, the first press-fit pin from TE Connectivity was introduced in the automotive industry. Today, TE Connectivity offers two distinctive press-fit solutions for automotive applications: ACTION PIN and Multispring pin.

TE’s press-fit solutions in fact are compliant pins featuring an elastic behavior and thus will deform during insertion (significantly reducing stress on the PCB holes compared to solid press-fit pin – which do no more exist in automotive applications) and sustain a permanent contact normal force when inserted to enable a reliable electrical and mechanical connection over lifetime.

Press-fit pin and plated through hole (PTH) summarize together to a press-fit system. The functionality of such a system is dependent of the properties / characteristics of both of the components and their interactions.

TE's Advantages for Compliant Pin Design

- Reliability – IEC norm shows it is minimum 10 times more reliable than soldering and IDC connections

- Press-fit miniaturization – NanoMultispring

- Fast manufacturing process

- No heat treatment required

- No need for high temperature plastics

- No thermal stress to connector

- No soldering mistakes like bridges bad wetting, flux residuals, cold solder joints, etc.

- Environmentally friendly – GREENER

Applications

- Airbag Control Units

- Sensors

- Convenience / Passive Systems

- Engine Management

- ABS / ESC Systems

10x

IEC norm shows it is minimum 10 times more reliable than soldering - IDC connections (breakdown rate in first fit)

60%

space-saving

25+

years proven automotive experience for best-in-class insertion zone.