USCAR-2 Compliant 0.50mm Automotive Connectors

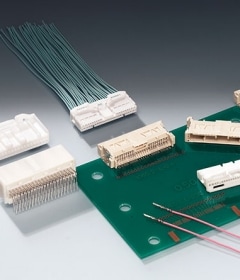

Small size. Big advantages. The TE Connectivity (TE) Generation 50 connector portfolio offers both size and weight savings while satisfying the USCAR-2 environmental and mechanical requirement for 0.50 mm systems.

USCAR

Qualified for USCAR 2 and 21 and compliant with USCAR 25

2-28

Circuit count covers a broad range of applications

1.8mm

Small header footprint and connector form factor

TE's Generation 50: Safer, Greener, Smarter. The Generation 50 supports customers designing, planning, or producing products where components that weigh less - and take up less space - can provide an advantage. The robust technology of the Generation 50 includes unsealed clean body design, anti-stubbing terminal beam geometry, that helps eliminate the risk of terminal push out, and allows for excellent insertion and stress distribution.

Light weight, space-saving design

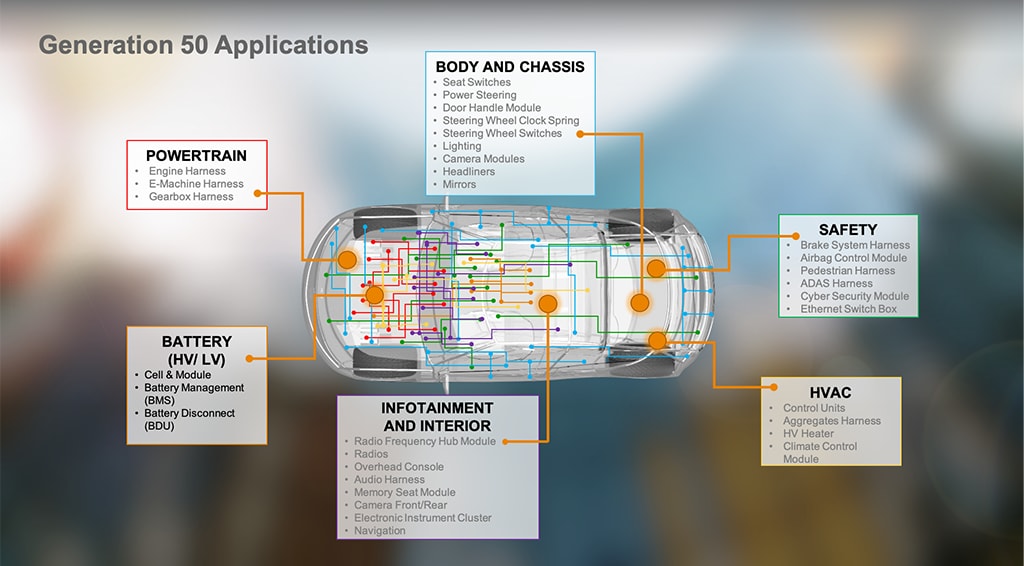

TE's innovative Generation 50 design can be used in a wide range of transportation products across numerous applications where its size and weight advantages can make a major difference in product design and planning.

Generation 50 Terminals

The Generation 50 terminals and connectors (plugs) are capable of wire sizes down to 0.13 mm² which reduces wire harness weight and improves ergonomic harness handling. At the same time the Generation 50 terminal is also a robust interconnection system offering an exceptional level of retention due to primary and secondary terminal locking features.

Benefits

- 0.35mm² to 0.13mm² wire size range

- Anti-stubbing beam geometry

- Multiple mating contact points

- Orientation and retention features

- Three wire barrel serrations for flexibility

- Terminal push-out prevention

- Optimized insertion and stress distribution

- Extra throw Independent Secondary Lock (ISL)

- Maximum wire oxide disruption

- 'Kojiri' design for secure mating

Generation 50 Connectors (Plugs)

TE offers outstanding savings in packaging space while ensuring the highest levels of automotive robustness. The Generation 50 connectors offer superior PCB retention forces of 80N in perpendicular direction to mating. In addition, options for click-audible connector position assurance (CPA), PCB mounting clips and anti-scooping features all contribute to the USCAR and GMW3191 compliant automotive levels of robustness. The connector system offers an anti-stubbing solution by providing a pin opening, receptacle opening and lead in funnel molded in the same piece of plastic.

Benefits

- Everything molded in same plastic

- Robust anti-scooping features

- Preset Independant Secondary Lock (ISL)

- Loud audible click during mating

- Anti-stubbing system preventing risk of terminal push-out during mating

- Header pin damage protection

- Shipment and handling damage prevention

- Fully mated operator feedback

- Meets USCAR specification for serviceability

- Connector Position Assurance (CPA) Optional

Generation 50 Headers

TE’s surface mount technology (SMT) headers offer excellent board retention and coplanarity technology to minimize and help eliminate connector assembly tolerances plus variations from the products overall coplanarity. Connectors are available with optional CPA and wire dress covers. The Generation 50 series offers right angle SMT headers and connectors on single and dual row configurations up to 28 positions on 1.8mm pitch and offer lower mating forces over traditional connector solutions.

Features

- Surface Mount Technology

- SMT coplanarity

- Press-Fit PIN technology (NanoMultispring)

Benefits

- Up to 49% PCB footprint reduction

- Reverse board processing

- Easy solder joint inspection

- Minimizes connector assembly tolerances