Trend Insight

Tips for Configuring Transducers

When searching for an LVDT Linear Position Sensor for an application, you often must decipher a multitude of product specifications to configure the right transducer.

Below are tips for specifying an LVDT displacement sensor to your requirements.

What is the measuring range?

Sensors are designed to work over certain measurements ranges. LVDT Linear Position Sensors are best suited to make measurements from roughly ±0.010 inches to ±10 inches. Granted, a few special cases exist outside that range, but the vast majority are within that range.

What is the application?

Understanding the broad application can go a long way in narrowing down the best type of LVDT mechanical interface. For example, to make quality measurement checks on an assembly line using an automated system or where the movement is not perfectly linear and some side-to-side motion can exist, a spring-loaded LVDT could be a good choice. These sensors are suited for use in assembly operations, machine tool, and production line inspection as well as quality control and testing labs.

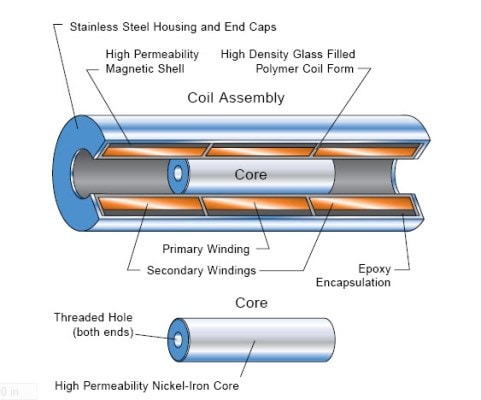

For a linear valve position measurement, a separate-core LVDT (see Figure 1) could be the best choice. Offering frictionless operation, free-core LVDTs are generally less expensive than guided core (spring-loaded) units and are available in many ranges and sizes.

Figure 1: A separate-core LVDT includes a moving element that is a separate tubular armature of magnetically permeable material called the core. Free to move axially within the coil's hollow bore, it is mechanically coupled to the object whose position is being measured. The output characteristics of an LVDT vary with different positions of the core.

Are there space restrictions?

Sometimes, customers have a limited amount of space in a fixture for an LVDT. If space is a concern, smaller LVDTs, such as TE Connectivity Miniature 3/8" LVDTs, can fit into tight places.

What are the environmental considerations?

If heavy dust, dirt, humidity, or jetting are present, or if the sensor will be installed outdoors, a hermetically-sealed LVDT is recommended to confirm outside media does not enter the windings that can shorten sensor life or reliability. In a more benign or indoor laboratory environment, a standard non-hermetically sealed transducer will get the job done with a lower up-front cost.

For in-cylinder applications with hydraulic fluid, a “vented” LVDT will perform well. Vented versions of LVDT linear position sensors can withstand a combination of high pressure, temperatures, shock, and vibration as the coil assembly of the sensor is vented to equalize pressure inside and outside the LVDT linear position sensor.

Special configurations of LVDTs also offer mild resistance to radiation and operation when submerged underwater or in high pressures or atmospheric conditions. For example, certain types of stainless steel cannot be used in LVDT construction when sensors come in direct contact with seawater. To survive in subsea environments, the LVDT casing should be constructed of special alloys that extend chemical resistance to seawater. These superalloys enhance the already high-reliability of the LVDT assembly, confirming that it can meet extended service life requirements, even if the device is fully exposed to seawater at depths up to 15,000 feet with external pressures of approximately 7500 psi.

Alloy 400 is a special nickel-based alloy that provides excellent resistance against pitting and attack by micro-organisms, enabling sensors to perform in shallow and warm waters with high levels of oxygen without the threat of sea life forming on it. In subsea applications with depths of 7500 ft. and external pressures surpassing 3500 psi, Inconel, Titanium, and Hastelloy offer excellent protection against corrosion due to higher content of nickel, chromium, and molybdeumn.

When designed with Alloy 625 or 718 for pressure and corrosion resistance, an LVDT assembly can provide reliable operations for many years, even if the device is fully exposed to seawater. While these alloys cost more than stainless steel, they offer immunity against localized corrosion as well as oxidizing and reducing elements. Exotic alloys such as cobalt, nickel, and chromium with mineral insulation can deliver even higher performance from LVDTs where comparable technologies will not survive.

What is the operating temperature?

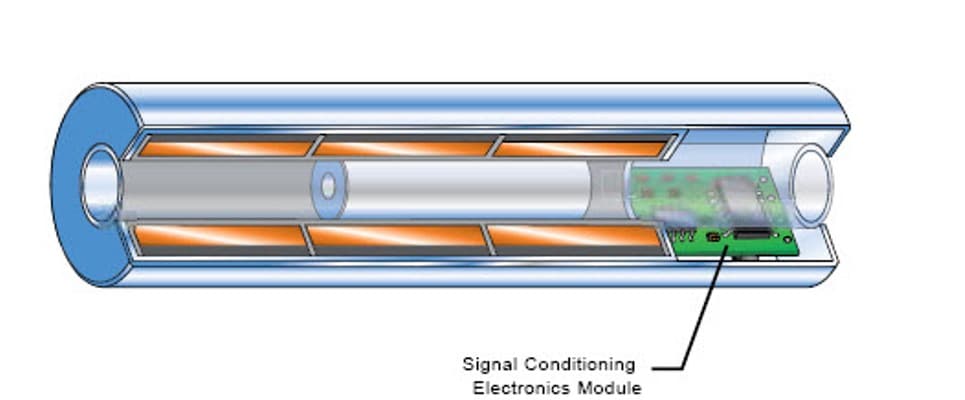

A DC-operated LVDT can be used at temperatures at or below 85°C. While a DC-operated LVDT can eliminate the volume, weight, and cost of conventional external AC excitation, demodulation, and amplification equipment, DC-operated units are limited by the properties of the materials in the electronic signal-conditioning module that is contained within the sensor (see Feature 2).

AC-operated LVDTs, on the other hand, can handle temperatures up to 200°C and even higher with remote signal conditioning electronics operating outside the unit in an environmentally-controlled area. Output can be displayed on a suitable readout and/or inputted into a computer-based data acquisition system for statistical process control.

What are the certification requirements?

When selecting a linear position transducer for use in hazardous operating environments, sensor users must be fully aware of the intended environment and location of its application as regulatory and safety requirements vary by country.

Sensors certified within the U.S. to UL ratings are not necessarily acceptable for use overseas, especially in hazardous areas such as those found in oil and gas applications, nuclear power plants, subsea as well as mining. In many countries, sensors must comply with specific national requirements to ensure safety and prevent accidents or disasters.

For example, in the European market, sensors specified for use within potentially explosive atmospheres must be certified to ATEX standards. Even if a sensor is designed for operation under hazardous conditions, units must be tested and assessed to the latest ATEX standards.