LITESURF plating technology

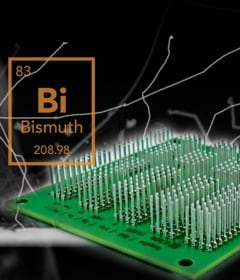

TE Connectivity’s new, sustainable LITESURF plating offers ultra-low risk of whisker growth in automotive electronic components. New bismuth (Bi)-based solution for press-fit plating applications can reduce the risk of whisker growth by a factor of over 1600 compared to tin-based solutions.

January 09, 2018

BENSHEIM, Germany - TE Connectivity (TE), a world leader in connectivity and sensor solutions, today announced the launch of its LITESURF plating technology designed to minimize the risk of whiskers that can short-circuit electronic components and cause potential system failure. TE’s new bismuth-based solution for press-fit applications can reduce the risk of whisker growth by a factor of over 1600 compared to traditional tin technology.

The increasing amount of electronics in vehicles has led component manufacturers to use press-fit technology for printed circuit board (PCB) connectivity. Plating is applied to the pins to assist with lubrication and protect against surface damage due to oxidization and other causes. Traditionally, plating solutions comprised of tin (Sn) and lead (Pb), but with the global phase-out of harmful substances pin plating solutions primarily consist of tin.

Tin does have its limitations, including the risk of whisker growth which occurs when tin film is stressed such as during pin insertion into a PCB. Tin whiskers can grow long enough to bridge to other metal components and, in extreme cases, cause electronic components to short-circuit leading to potential system failure. As a result, automotive component manufacturers are seeking new alternatives.

“Automotive manufacturers recognize the benefits of reliable solder-free technologies such as press-fit, but want to eliminate risk of whisker growth,” said Frank Schabert, senior manager of R&D at TE Connectivity. “Our LITESURF plating technology is based on bismuth, a harmless substance with all the favorable characteristics of tin but with ultra-low whisker risk. It can easily replace tin on a production plating line with minimal process disruption.”

Learn more about TE’S LITESURF plating technology here.

Media Relations:

April Klimack

TE Connectivity

+1 717 599-1495

DISCLAIMER: This document reflects the state-of-the-art result of the work of TE Connectivity (TE). While TE has made every reasonable effort to ensure the accuracy of the information in this document, TE does not guarantee that it is error-free, nor does TE make any other representation, warranty or guarantee that the information is accurate, correct, reliable or current. TE expressly disclaims all implied warranties regarding the information contained herein, including, but not limited to, any implied warranties of merchantability or fitness for a particular purpose. The document is subject to change without notice. Consult TE for the latest dimensions and design specifications.

LITESURF, TE, TE Connectivity, the TE connectivity (logo), EVERY CONNECTION COUNTS are trademarks of the TE Connectivity Ltd. Family of companies.

About TE

TE Connectivity is a global industrial technology leader creating a safer, sustainable, productive, and connected future. Our broad range of connectivity and sensor solutions enable the distribution of power, signal and data to advance next-generation transportation, renewable energy, automated factories, data centers, medical technology and more. With more than 85,000 employees, including 8,000 engineers, working alongside customers in approximately 140 countries, TE ensures that EVERY CONNECTION COUNTS. Learn more at www.te.com and on LinkedIn, Facebook, WeChat, Instagram and X (formerly Twitter).