Lower Applied Cost for Compact Motors

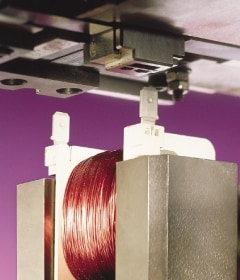

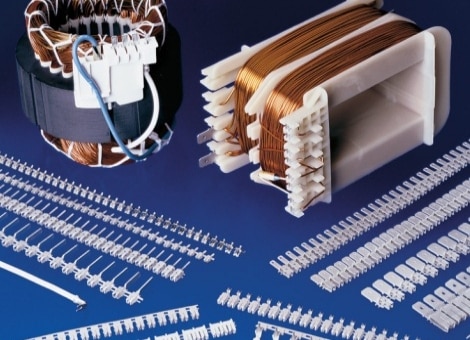

SIAMEZE insulation displacement contact (IDC) terminals bring high-speed, solderless magnet wire termination to space constrained, small motor systems. The IDC terminal features a moving beam contact to fit a wide range of magnet wire sizes in a single terminal. SIAMEZE terminals can be applied with automated or manual assembly to achieve stable, gas-tight connections of either copper or aluminum magnet wire, without the need for pre-stripping. The system offers multiple terminal interface options, including quick disconnect tabs, posts, receptacles, and wire-to-wire IDC with an optional Lead Lok strain relief device.

Product Features

| IDC Zone (in.) | .220, .300, .550 |

Input / Output Types | Wire-to-wire, Wire-to-blade, FASTON Tab, Solder Post, Eye of Needle, Round Pin, Leaf Spring |

| Wire Size (mm / AWG) | Cu: 0.13-2.03 / 36-12 Al: 0.40-2.30 / 26-11 |

Materials / Plating | Base: Brass, CuNiSi, CuCrSiTi Plating: Tin, Pre-tin, Unplated |

| Max Number of Wires | Magnet Wire: 1 Lead Wire: 1 |

Single Cavity Dimensions (in.) | Min: .270H x .276W x .104T Max: .630H x .410W x .135T |

| Max Wire Diameter Ratio | N/A | Max Operating Temp. (°C) | 150 |

| Type of Wire | Magnet Wire (Cu / Al) & Stranded Lead Wire | Agency Approval(s) | UL |