What is a Heavy Duty Connector (HDC)?

An HDC connector is a rectangular, robust industrial connector designed to transmit power, data and signal in the harsh environment applications.

What are the appropriate applications for Heavy Duty Connectors (HDC)?

Typical applications include robotics, automation, machinery, rail and power applications.

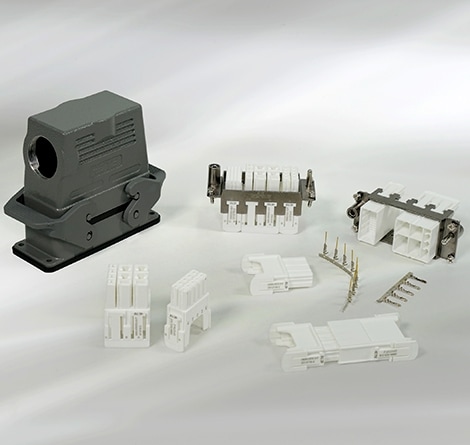

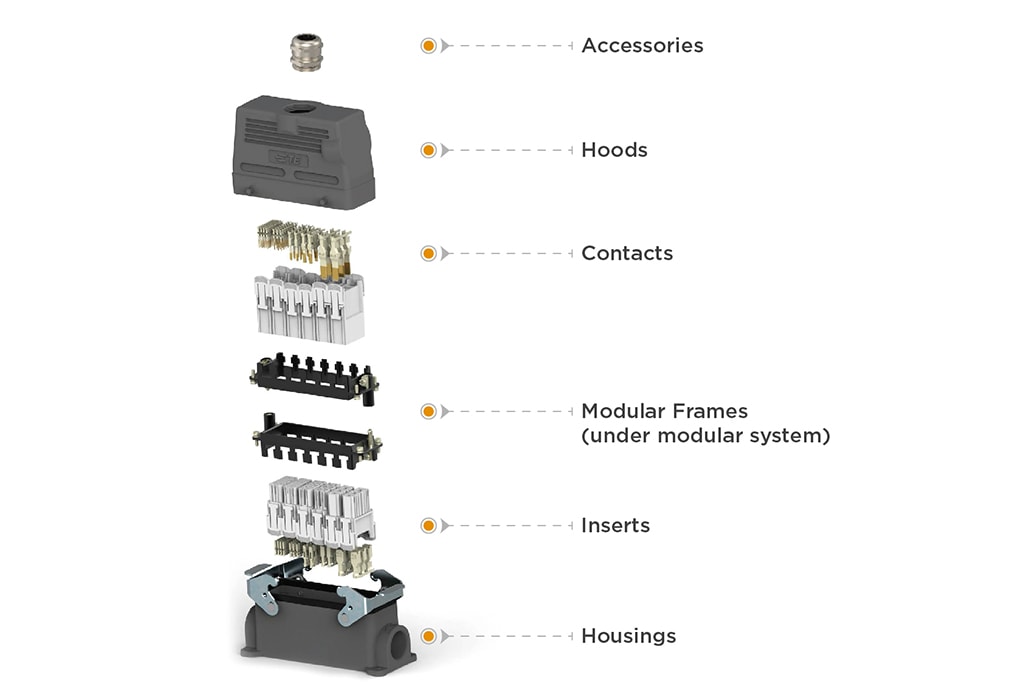

What products does the Heavy Duty Connector (HDC) portfolio consist of?

The HDC portfolio consists of:

- Hoods, housings and bases: available in different protection degrees IP65, IP67, IP68 and IP69k

- Contact systems: ranging from 5A to 650A in screw, crimp and cage clamp termination

- Inserts: available in up to 216 pins in one connector for crimp, screw termination or cage clamp

Read More: Heavy Duty Connectors FAQs