Engineering for tomorrow's challenges

In our 11 engineering laboratories across Europe, India, China and the US, TE Connectivity (TE) engineers are developing highly durable, ruggedized, and rigorously-tested solutions.

In our laboratories, TE engineers perform rigorous product testing, the core component of our product development path. The goal is to build customer trust in the quality and performance of the TE products they use. This trust is also built by partnering with our customers to develop and test unique connectivity solutions for their applications. Through partnerships, we work closely with our customers to check the performance and quality of products installed in the field, such as TE's SIMAFLEX high voltage connector system for substation or our insulation piercing connector for low voltage aerial network. We also collaborate with our customers to define their technical specifications, enhance their designs, and develop unique, custom products at their request.

40+

People working in our engineering laboratories

20+

Engineers sitting at standardization committees

11

Laboratories located all around the world

Our railways customers often visit our engineering labs for collaborative support in catenary design. We work closely together to develop and optimize solutions for their applications.

- Stephen Heffernan,

- Engineer, Insulation & Protection Laboratory, Limerick, Ireland

Facilities Near Our Customers

TE's engineering teams develop, test, and prove the electrical performance, mechanical reliability, and aging resistance for products new and tried-and-true, for such applications as:

Insulation & Protection (I&P)

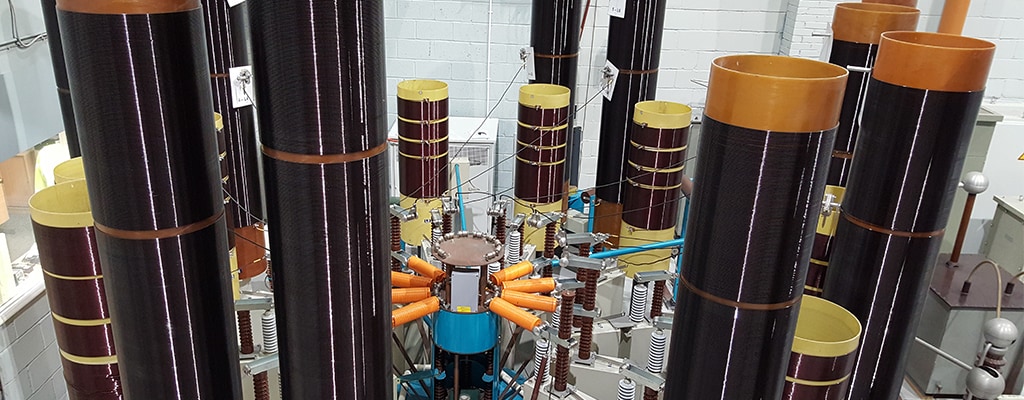

The I&P principle electrical and mechanical laboratory is situated in Brighton, England and has been for over 40 years. It is equipped to perform component and surge arrester R&D and qualification testing to the latest statutory national, regional and international standard requirements. It has test equipment which is customized to the surge arrester industry, which can deliver high voltage, high current and high energy simultaneously and/or sequentially for electrical tests as well as post-test evaluation after mechanical test procedures. The laboratory is complemented by a team of highly skilled and well qualified electrical and mechanical engineers whom are either fellow or member of their professional institutions.

The lab located in Limerick, Ireland performs mechanical and electrical tests for products from our I&P portfolio, such as insulators and surge arresters. TE engineers conduct mechanical tensile and cantilever tests up to 200 kN on the INSTRON and can perform AC withstand, DC interface leakage current testing in the high voltage (HV) laboratory Brighton. Test processes include hardness, roughness, and dye penetration; this facility can boil and bake samples in order to assess aging performance.

High power impulse test system in Brighton, England laboratory

Connectors & Fittings (C&F)

Laboratories in Gevrey-Chambertin, France and Witham, UK are hubs of connectivity innovation, for products such as connectors equipped with high-current capabilities. During the final stage of development, the laboratory team performs the standardized tests required to fulfill the qualification process. An accredited ISO 17025 facility since 1994, the laboratory offers 21 test competencies and performs more than 200 tests each year.

The test laboratory in Witham tests connectors and fittings, cable joints and other low voltage (LV) accessories (i.e., underground link boxes), testing them to various standards, typically BSEN61238-1 (connectors), BSEN50393 (cable joints), C93 (earth bonds) and ENA TS 09-23.1.2014 (link boxes).

In our testing-laboratories, we can validate the theoretical approach as we develop products that meet the high standards of our teams, customers, and their market.

- Patrick Bastiancig,

- Manager, Connectors & Fittings laboratory, Gevrey-Chambertin, France

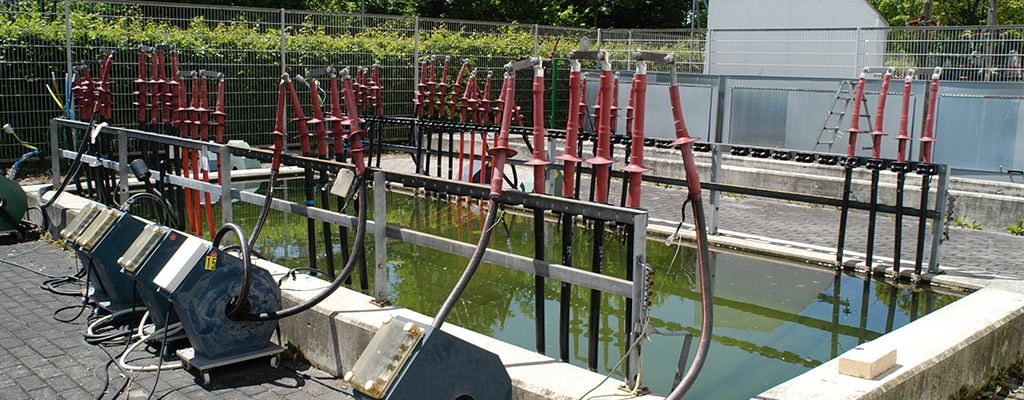

Outdoor testing for cable accessories in Ottobrun, Germany laboratory

Cable Accessories

In Ottobrunn, Germany, one of our largest laboratories, we test joints, terminations, and switchgear connectors from 400 V up to 245 kV within the 2400 m² indoor, or 600 m² outdoor testing areas. Our facility has been accredited per DIN EN ISO/IEC 17025:2018 by DAkkS (“Deutsche Akkreditierungsstelle GmbH”), the national accreditation body in Germany.

Our engineers run type tests according to CENELEC – HD 629, IEC 60840, or IEC 62067 (up to 245 kV). This laboratory also performs sustaining tests to check product performance and quality, as well as customer specific tests. Per year, 40+ tests are witnessed by customers. In addition, TE engineers test the full range of specifications, including:

- Impulse level, partial discharge and other electrical parameters

- Environmental conditions

- Exposure to salt and humidity

- Pressure variations

For a full list of testing methods available, please click here.

Materials

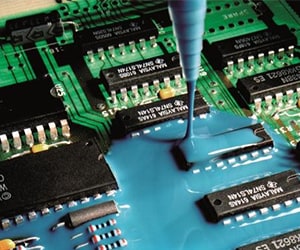

Unique to TE are its four materials labs. They enable our engineers to both create new compounds and assess the key functional characteristics of materials, which enables the validation the compounds of 40+ years of product-life service. Engineers in Berlin, Germany develop casting and coating materials for electronics as well as the insulating resins used in electrical installation applications.

In Swindon, United Kingdom and Vasai, India laboratories, TE engineers compound and mix proprietary materials used in new product development and sustaining projects. We test and analyze the mechanical, electrical, thermal, and environmental properties of both materials and products. We also participate in the creation of prototype products for validation and product approval testing.

Capability, Experience, Optimization

With laboratories located in regions close to our customers and their markets, we provide the unique capability to respond quickly to customer requests for product testing requests. Customers participate in the testing process so that they can witness the testing first-hand. The result is faster turnaround for less cost. Our internal capabilities enable us to build stronger relationships with our customer, which helps reinforce TE’s position as a leader with the infrastructures to meet customers’ expectations.

Working with TE engineers is also the insurance of partnering with people who have a long experience, not only in the laboratories, but also in the field. Customers receive collaborative support from experts in facing their challenges.

By partnering with TE engineers, customers gain an advantage in contributing to – and witnessing the development of – unique solutions to address their difficult connectivity challenges. For example, in the Limerick and Berlin laboratories, we provide field failure analysis services, advice on specification enhancements, and support on tooling.

In Ottobrunn, we offer highly flexible product testing, even with very specific requirements.

Our Materials Engineering laboratories combine more than 200 years of materials knowledge and experience within the highly skilled members of these labs.

- Dave Pearce,

- Senior Manager, Materials Engineering Laboratories, Swindon (UK), Ottobrunn (Germany), Vasai (India)

Setting the market and international-standards

In operating some of the most well-respective testing laboratories, run by teams that included more than 20 engineers who serve on international standards boards, TE is helping create the protocols and practices that will shape tomorrow’s connectivity. From IEC to IEEE, and ANSI to CENELEC, our engineers and scientists are helping establish crucial performance standards that will advance electrical power solutions for the future. For our customers, they gain the confidence that their products use meticulously tested connectivity solutions that are engineered to perform under the harshest conditions, in the most extreme environments.