New Solutions for the use of Aluminum Magnet Wire in Motor Designs

Our new innovative wire termination solutions are designed to solve for the challenges facing today's engineers

Manufacturers are focusing on the materials being used in motor designs to help manage costs, while at the same time looking to improve quality and consistency in their manufacturing and operating processes.

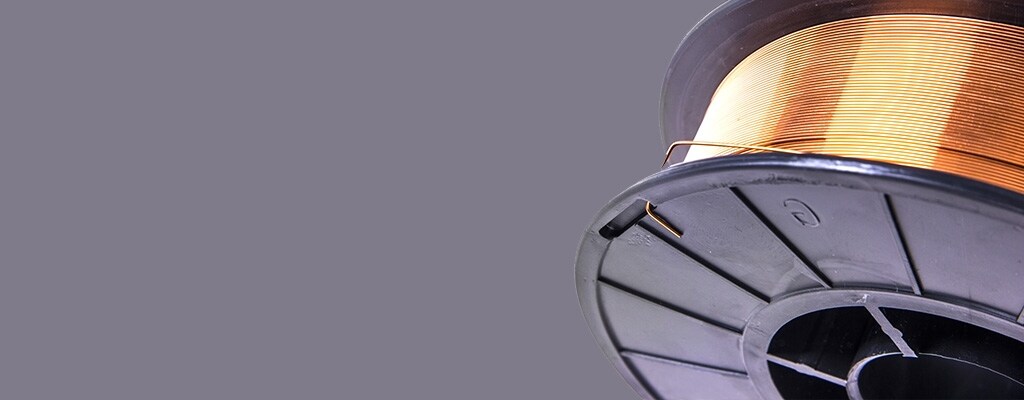

ALUMINUM MAGNET WIRE IS MORE COST EFFECTIVE THAN COPPER MAGNET WIRE

THE PRICE OF ALUMINIUM IS NOT SUBJECT TO THE LEVEL OF MARKET FLUCTUATIONS AS THE PRICE OF COPPER

ALUMINUM WIRE WEIGHS LESS THAN COPPER WIRE

DESIGN TRENDS AND CHALLENGES

COST EFFECTIVENESS

While the actual savings depends on the final product specifications and efficiency requirements, if you consider just the base material, we estimate that for achieving the same equal electrical conductivity, manufacturers using aluminum magnet wire vs copper magnet wire could see up to 45% lower material cost.

WEIGHT

On average aluminum is one third the weight of copper. For electric motors with many coils and bobbins, such as those used in transportation vehicles, the reduction in weight from using aluminum vs copper magnet wire can provide savings in transportation/freight costs as well as potential savings in end users gasoline consumption.

MARKET VOLATILITY

Motor manufacturers across all industries are continuing to be impacted by the fluctuating market prices of materials. While both aluminum and copper metals adjust as the market changes, however aluminum does not appear to be subject to the same extreme price increases as can be seen with copper.

Our Newest Product Solutions for Aluminum Wire Termination

We are introducing two new products that have been specifically designed to address the trend in the market of replacing the use of copper magnet wire with aluminum magnet Wire

- MAG-MATE Terminals with Multispring Pin for Al Magnet Wire

- SIAMEZE Terminals for Al Magnet Wire

e

e

e

e

e

e